Development Time Ratio Considered Harmful

When I introduced range timers to Typica, one of the first requests that came in from several people was if it would be possible to have Typica report these time ranges as a percentage of total roasting time. Of course it would be trivial to modify a Typica configuration to do this, but I don't intend to do that myself as this is a terrible idea.

One of the easiest ways to start understanding roasting data is to understand how different sorts of changes happen in different parts of the roasting process. Looking at roasting data from this perspective allows you to look at different parts of the roast and observe how changes in that part of the roast affect what comes out in the cup. Range timers provide a way for Typica to capture the amount of time it takes for the roast to pass through a range of temperatures. So what's the problem? If someone wants to think about their roasts in terms of the percent of time spent in different ranges, once you have a total duration it's easy to switch between duration and ratio notations. The problem is that there is nothing that changes in coffee in relation to a percent of total roasting time. You reach the activation energy of a given chemical reaction, the reactants are present, that reaction starts happening and will continue for as long as the conditions required for that reaction are present. Future knowledge of how long the batch will take can not influence this.

Digging a little deeper, everybody who wanted this feature wanted it as a quick and easy check on quality at the roaster. You hit a 20% development time ratio, the coffee will be good, no need to taste it. That would be a tremendous time saver if it worked, but it doesn't. In fairness, I think that proponents of development time ratio who have done work supportive of their views never intended this to be taken as a post-roast quality assurance metric, but it is clear that people who have not conducted their own experiments would like to use it that way. There is no substitute for tasting everything, but if you must target your quality assurance tastings you need a metric or set of metrics that will reliably minimize the number of in spec roasts flagged for evaluation and maximize the number of out of spec roasts flagged. Using development time ratio for this can only encourage roasters to produce out of spec roasts to game the evaluation metric. The results would be exactly opposite the intent.

When using metrics to evaluate production consistency, it is important to pick metrics that relate to production consistency.

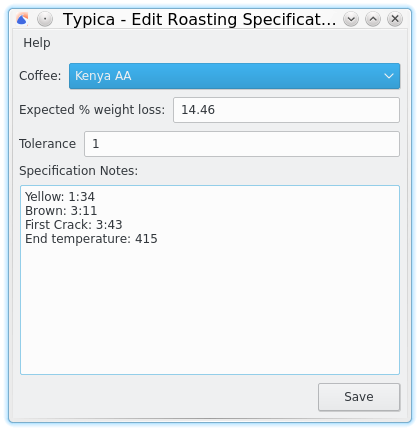

Fortunately, Typica has a better option. If you go to "Edit Roasting Specification" you'll find a few fields that you can set for each roasted coffee item you have. The first two are related to percent weight loss. When entering new batch data Typica will display a range of how much roasted coffee you can expect to get at the end of the batch based on this information and relevant reports will color the percent weight loss based on if this is in spec or not. Below that are specification notes that will also be displayed when entering batch data. Here you can put in times expected from your range timers for easy comparison with the results reported at the end, but you can use this for more than that. For example, if you have a roast development meter or color reference, you can include color in your specification and easily check that at the end of the batch. Time within significant ranges, ending temperature, percent weight loss, and color taken together work very well to determine that a coffee will taste the same as a batch of the same green coffee roasted to the same spec. I want to especially note that time within significant ranges has a plural. Different parts of the roast affect different aspects of the flavor of the coffee and not all ranges are significant to the end result in the cup (see The Pre-Roast). Any single range in isolation is only meaningful in the context of controlled experiments on changes in that range. For good quality assurance metrics you'll need multiple significant ranges.

I would not recommend relying on this completely. Someone might still pick the wrong green coffee, for example, leading to data that might look good for coffee that tastes wrong that might not be apparent until examining inventory records. If you can't taste everything, at least include a random sampling of things you believe are in spec.

It is also possible to record sensory specifications for your coffees. I recommend having two sets of sensory specs, not necessarily in Typica. One should be for cupping observations. If you have a lot of coffees to evaluate it's often easiest to just put them all on the cupping table. The other set should be for tasting brewed coffee. This is especially useful in a cafe environment as it provides a reference for your bar staff to participate in the quality assurance process. The barista, if appropriately empowered, serves as the last line of defense between an out of spec coffee and a dissatisfied customer. They should be encouraged to taste the coffees and ensure the coffee tastes as it should. If it doesn't, that might indicate improper brewing, but a skilled barista can determine if that's the case and correct that issue. Once that possibility is ruled out, they should be able to tell the roaster that the coffee is out of spec and not sell that coffee to customers.

Typica: Software for Coffee Roasting Operations

Typica: Software for Coffee Roasting Operations